Most people understand that buildings outfitted with secure, storm-resistant roofing material like metal are less prone to damage from hurricanes, hail storms and other damaging weather events. Not only does this strength provide safety and security for the building owner, but those qualities also translate into cost-savings outside of what’s saved due the longer lifespan and lower maintenance requirements of metal panels.

Safety in Strength

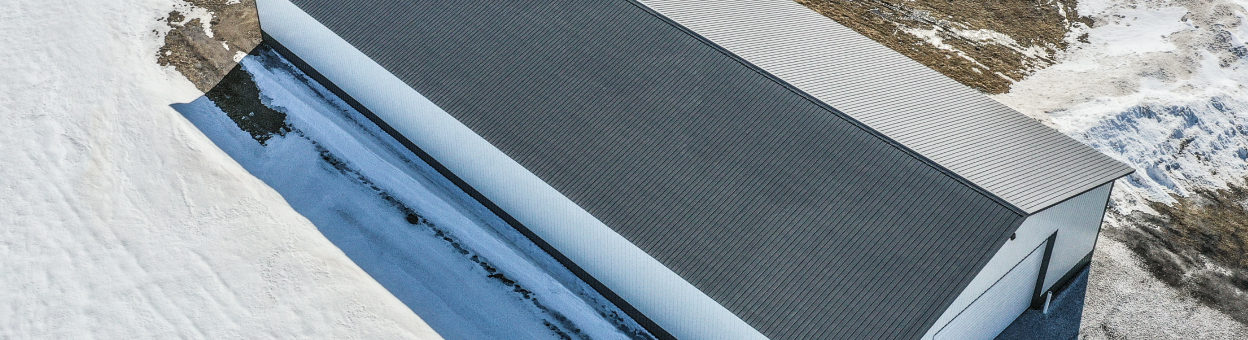

Metal roofs are made to last. Thick panels, properly installed and maintained, have a lifespan of up to 50 years under normal circumstances—double that of most asphalt shingle roofs. To ensure that lifespan, metal roofing manufacturers perform rigorous tests (according to strict ASTM standards) that document performance under a range of environmental traumas. These tests confirm that, compared to other surfaces, metal offers superior performance when subjected to the following:

Hail

Even the most basic metal roof is a shield against hail damage, but of course some products and roof designs offer even greater protection. To protect against hail damage, the optimal option is a heavy-gauge metal panel roof installed over solid plywood or oriented strand board (OSB) sheathing. Two of the most comprehensive post-storm studies found that such roofs survived even the biggest hailstones without punctures or leakage.[i] In the worst cases, the damage to the metal was only cosmetic.

Wind and water

Metal roofs can withstand wind gusts as strong as 140 mph. Because they consist of large interlocking panels, they’re less susceptible to uplift than individual asphalt shingles and offer fewer entry points for water.

In addition, the synthetic underlayments used by professional roofers are 20 times stronger than felt, so in the unlikely event that the roof is punctured there is a much lower chance that water will get into the structure. (Synthetic underlayments also stay as much as 25 degrees cooler on a hot, sunny day and include an anti-skid coating that keeps roofers safer during installation.)

Wildfire

We’ve all seen pictures of metal-roofed homes that have survived wildfires while the surrounding structures burned to the ground.[ii] It makes sense: metal panels hold a Class A fire-resistant rating (the highest possible), making a metal roof installed over a fire-resistant cap sheet the optimal combination in fire-prone areas. In fact, a publication from the UCLA School of Architecture urges homeowners rebuilding in wildfire zones to use non-combustible roofing and siding. It also cautions against the use of clay tiles, which can develop cracks that allow wind to drive burning embers into the attic.[iii]

Lightning

Many people ask about metal roofing’s lightning resistance: does its conductivity make it more susceptible to strikes? The answer is no: not only is a home with a metal roof no more prone to this than any other structure, but if it is struck by lightning the large metal surface will do a good job of safely dispersing that energy.[iv] And because metal is not flammable, a strike is much less likely to start a fire, which is often the most devastating result of a lightning strike.

Continual Savings

Confirmation of metal’s durability and safety comes from a third party business with a real stake in the matter: the insurance industry. Some insurance companies offer lower premiums for the use of qualifying wind- and impact-resistant roofing materials like metal. These include large national insurers like State Farm and Nationwide, which offer discounts in 26 states plus one Canadian province for certain roofing products with Class 4 wind ratings. Most metal roofing manufacturers, including American Building Components, have several products on their lists.

For more information on ABC’s roof products, please visit our website or contact your local representative today.

[i] http://www.constructionmagnet.com/metal-roofing-magazine/metal-vs-mother-nature-hail

[ii] http://photoblog.nbcnews.com/_news/2012/08/16/13314843-lone-house-surrounded-by-scorched-earth-survives-wildfire?lite

[iii] http://www.energy-design-tools.aud.ucla.edu/FIRES.html

[iv] http://www.metalroofing.com/v2/content/guide/newsletters/04-0701.cfm