Metal roof and wall trim is used to seal joints and edges to keep moisture out while providing a seamless transition between panels to create a polished look. With our online ordering tool, you can browse our selection and order the trim your customers need from anywhere at any time. Learn more about ordering trim online!

Online Trim Options

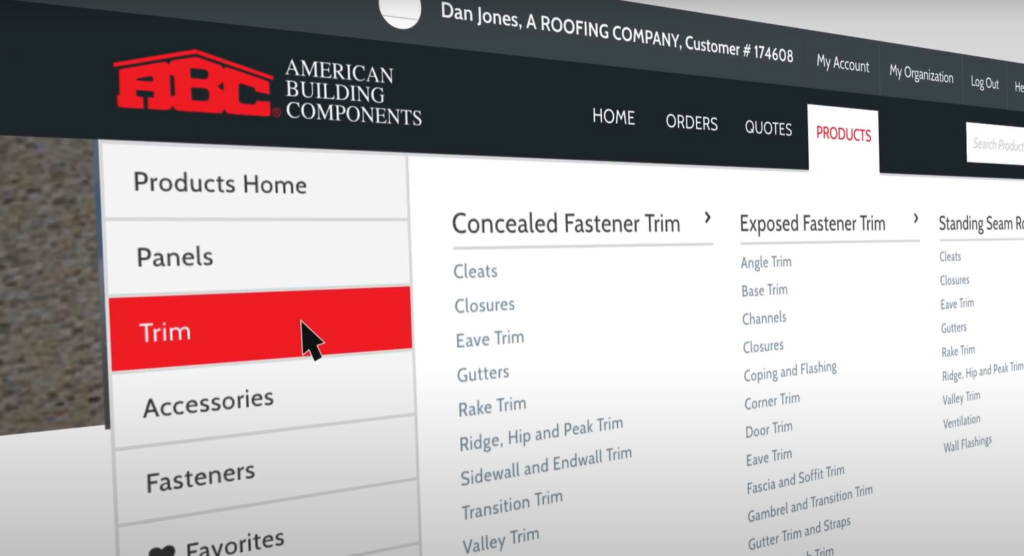

Our metal roofing and wall trim is available in all standard colors to match our panels. The trim style and profile you select should depend on the panel profile used on your building project. When ordering through the ecommerce platform, there are four main trim categories to choose from:

- Concealed Fastener Trim – used with our SL-16 Panel

- Exposed Fastener Trim – used with multiple profiles, such as Imperial Rib and PBR

- Standing Seam Trim – used with LokSeam

- Custom Trim – used in a variety of applications

All ecommerce manuals are organized based on the panel groupings, indicating the correct type of trim for each panel. Choosing the proper trim is important because the following variables are different for each panel profile:

- Rib Heights

- Rib Spacing

- Installation Methods

- Attachment Methods

Ordering Custom Trim

ABC Metal Roofing makes it easy to order custom trim to meet your specific needs. Just like our standard trims, special trim is available in all of our standard colors, with length options up to 20 feet. ABC also sells flat sheets and coil stock, if you prefer to fabricate your own trim items. Learn more about how to order:

How to Draw Trim

When drawing your trim, keep these points in mind:

- All dimensions must be noted in inches with a tolerance of 1/16 of an inch

- Custom trim can be produced in lengths of up to 20ft.

- Color side must always be noted

- Label all degrees of bend

- Trim ends can be hemmed (the standard is ½”)

- Label each trim with a piecemark of your choosing to help identify the special trim throughout order and production process

Special trim drawings must be submitted online before the order can be completed. Each customer has the option to upload their own saved document or download and edit a standard template.

Pricing

All custom trims are priced based on the total square footage of each part. Each gauge and color system has a unique cost per square foot. Bends are priced at $0.80 each while hems are $1.60 each.

If you’re planning to reorder the same trim, we can work with you to set up a unique part number to make it easier to reorder.

Placing Your Order

Browse our selection of trim to find the best fit for your customer’s project. Visit our online ordering tool to place your order today! Not a registered user? Register for an account to access this convenient tool.