Our metal roofing panels are designed for durability, featuring a baked-on paint finish that covers the Galvalume®-coated steel surface. This helps to preserve the look and functionality of your metal roofing panels for decades with minimal maintenance. Over the life of your metal roofing panels, however, it is possible that the baked-on paint finish can be damaged. For minor scratches, you are able to use touch-up paint to preserve the aesthetic appeal of your metal roof. Learn more about selecting and applying metal roofing touch-up paint.

What Causes Scratches & Dents?

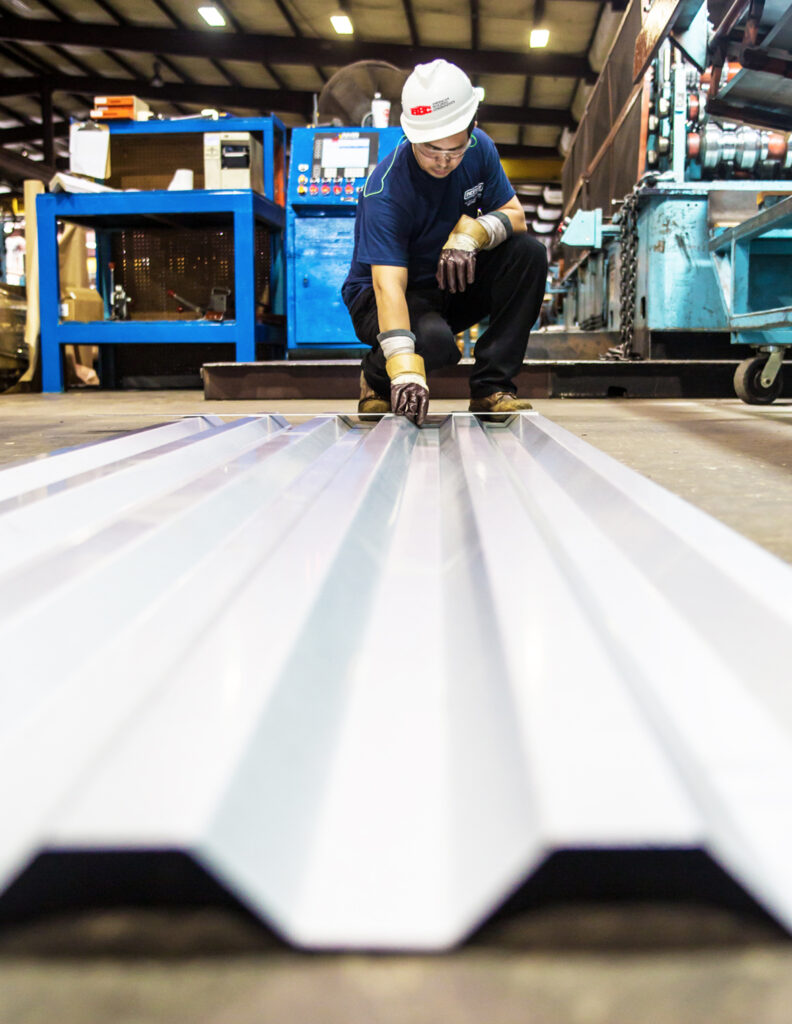

Metal roofing panels are most commonly damaged during the installation process. To avoid scratching or denting your metal roofing panels, it’s important to store them properly and use caution when unpacking and installing them. Store them at a slight angle in a dry location that is out of the way of foot traffic and ongoing construction. Avoid dragging panels across each other when unbundling to prevent damage to the paint coating.

After metal roofing panels have been installed and before the installer leaves, walk around the building to look for scratches and dents within normal view. Address these issues with your installer.

After the installation process is complete, there are additional considerations to protect your metal roof from damage. Keep trees trimmed to prevent overgrown branches from scratching your metal roof panels. Additionally, use caution when walking on the roof or using tools as these activities could damage the paint coating. Check your roof for damage at least once a year as part of your annual maintenance routine to keep it in good condition.

Assess the Damage

If you find a scratch during routine maintenance or a post-installation check, start by assessing the damage. How noticeable is the scratch? Is the panel scratched down to the bare metal? These are important questions to ask when deciding whether to use touch-up paint or replace the panel altogether.

Use touch-up paint for light scratches that only affect the paint coating or for hairline scratches down to the bare metal. touch-up paint fades more quickly than the baked-on paint coating, especially with bright or dark colors. As a result, covering a sizable area with touch-up paint could create more of a problem as the touch-up paint begins to fade over the next couple of years which would be more noticeable than leaving it alone. If your panel has large scratches or gouges that go down to the bare metal, consider replacing it instead.

Choosing Touch-Up Paint

When choosing touch-up paint for your metal roof, it’s important to make sure that it’s compatible with the existing paint coating. The best way to do this is by purchasing touch-up paint from your metal roof panel manufacturer. Most manufacturers offer small containers of high-quality paint that are designed to match the color of your existing roof panels.

How to Apply Touch-Up Paint to Metal Roofing

When applying touch-up paint, make sure to read the specific instructions provided by your manufacturer.

In general, you will complete the following steps to apply touch-up paint:

- Make sure the surface temperature of your roof is 50 F.

- Clean the area by wiping it down with isopropyl alcohol. Make sure the surface is dry and free from contaminants before moving on.

- If the bare metal of the panel is showing, apply acrylic primer.

- Apply touch-up paint to the area using the dobber (or a small artist brush). Multiple coats may be likely to achieve the desired film thickness.

- Touch-up paint should be tack free within 30-45 minutes.

- It should dry completely within 24-48 hours.

For more information on how to touch-up your metal roofing panels, contact your local ABC sales representative.