As the housing market continues to grow, so does the market for new construction homes and repair and remodel of existing homes. With the enhanced focus on sustainability and energy efficiency as well as new exterior design trends, metal roofing has become a popular option for homes across the country. As a result, the residential roofing market has grown at a rate of 14% per year.

Why are so many homeowners choosing metal roofing? In addition to its durability and sustainability, metal roofing offers superior design flexibility to fully customize the exterior of the home. Learn more about the aesthetic benefits of metal roofing for every home style.

Aesthetic Benefits of Residential Metal Roofing

The roof makes up a significant part of your home’s exterior, so it’s important to make the right choice. Metal roofing is the best option for your home as it offers superior design flexibility compared to traditional roofing materials. It is also a great choice to make your home stand out from the rest of the neighborhood.

Customizable

Residential metal roof panels come in a variety of styles, profiles and colors to complement every home style.

Create your desired exterior home aesthetic with a broad range of metal roofing colors from earth tones to bright colors and everything in between. Choose bold red or blue shades to make your home stand out. To create a natural looking home exterior, add a touch of brown, gray or green to your roof.

Eye-Catching Accent

One way to add curb appeal to your home is to mix and match materials. Using a variety of textures on your home’s exterior adds dimension and visual interest. Even if you’re not planning to install a complete metal roof, you can still use metal roofing as an accent. Consider installing metal roof panels on your covered porch and dormers to make your home stand out.

Fits Any Home Style

Metal roofing is a timeless option for every home style, from contemporary to classic, adding texture and dimension to your home’s exterior. Depending on the style of your home, metal roofing can add a touch of modernity or create the rustic charm that you’ve always dreamed of.

|

Ranch Metal roofing adds a touch of rustic charm to traditional ranch style homes. When selecting metal roofing colors, it’s important to choose a color that complements the brick exterior. Light, natural tones such as browns and grays are ideal for this home style. |

|

Craftsman Craftsman homes are known for their rustic charm and are typically designed with natural materials such as wood, stone and metal. This makes metal roofing a perfect fit for your Craftsman-style home. Natural roofing colors such as browns, blues and grays are a great option to complement exterior cladding and accents. |

|

Colonial The architecture of Colonial-style homes is defined by the roofline and evenly spaced exterior features such as windows and columns. Metal roofing is a great option to add a classic touch to your Colonial home. Choose from a variety of bold metal roofing colors to create contrast and highlight the symmetry of your home’s exterior. For a more neutral look, consider traditional colors such as gray, brown and blue. |

|

Tudor Tudor-style homes are defined by mixed materials, half-timber framing and steeply pitched roofs. With the steep pitch, your roof will be highly visible, making it even more important to select a durable, aesthetically pleasing material like metal roofing. To complement the brickwork and accents on your Tudor-Style home, consider dark metal roofing tones such as browns and grays. |

|

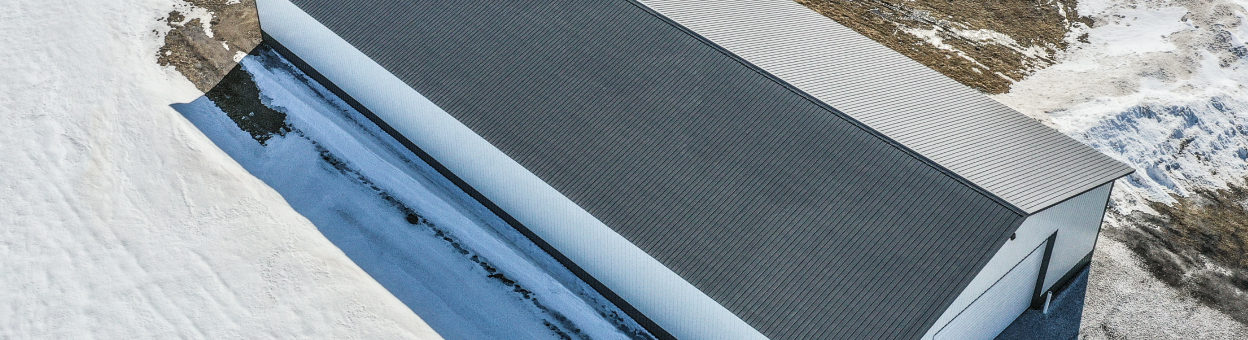

Modern Modern-Style homes typically feature clean lines and low-pitched roofs. Although the low pitch roof is not highly visible, it can still create a bold contrast for your home’s exterior. Metal roofing is an ideal choice for modern homes as it is available in bold, eye-catching colors, such as black and blue, to highlight unique architectural features of your home. The sleek lines of metal roofing also contribute to the modern look. Use our metal roofing color visualizer tool to discover how metal roofing will look on your home. |

Achieving the “Modern Farmhouse” Look

The Modern Farmhouse is becoming popular with homeowners. It is characterized by a gable roof, featuring a top ridge and sloped sides that create a triangle. When deciding on roofing materials to achieve this style, homeowners have increasingly chosen standing seam metal roofing, as it delivers traditional rustic charm with a touch of modernity.

Modern Farmhouses typically feature a solid white exterior, relying on a variety of architectural features and accents to add curb appeal. To create visual interest, pair dark colored accents with light colored siding.

|

For example, adding black exterior windows and a black metal roofing will create eye-catching contrast with white siding. |

Metal roof panels come in a broad selection of bold colors that are ideal for creating contrast against the white exterior cladding. Not interested in a complete metal roof? Add metal roof panels to your covered porch or dormers to mix and match textures.

How Much Does Residential Roofing Cost?

Residential metal roofing is a bigger upfront investment than traditional roofing options, but it ultimately provides long-term value that you can trust. While most asphalt roofs have a lifespan of 15-20 years, metal roofing can last up to 60 years. With the durability and longevity of metal roofing, you’ll see your investment pay off after 10 years.

Hidden or concealed fastener panels are typically a more expensive option, offering sleek lines without exposed screws. For a more cost-efficient solution, explore exposed fastener metal roofing.

Why Choose Residential Metal Roofing?

Residential metal roofing is a value add for your home. It offers the design flexibility you want with the energy efficiency, durability and cost effectiveness that you need. Contact an expert today and learn more about these popular residential metal roofing styles:

|

5V Crimp – Ideal for coastal regions, this panel offers rustic charm with a contemporary mill-style finish. |

|

SL-16 – This concealed fastener panel offers a clean, straight line appearance to add a modern touch to any home. |

|

LokSeam – This snap together panel offers a sleek appearance that is ideal for adding a touch of modernity to your home’ exterior. |