Metal panels are ideal for agricultural buildings, including those that house livestock, such as cattle, hogs and poultry. They’re durable and offer flexibility in design so you can create an agricultural building that is functional and aesthetically pleasing. Read below to learn more about the benefits of choosing metal panels and special considerations for animal confinement.

Why do so many agricultural buildings use metal panels?

- Durability: Metal panels are designed for durability. They can withstand high winds and heavy snowfall. They’re also hail resistant, featuring a class 4 rating. Unlike wood, metal panels are resistant to damage from termites and other insects. Metal is also noncombustible.

- Longevity: Metal panels last three to four times longer—up to 60 years. Unlike corrugated fiberglass panels, metal doesn’t get brittle after years in the sun.

- Cost Savings: Metal is a much more cost-effective material than wood because it doesn’t need to be replaced as often. The durable design of metal panels also saves money on maintenance.

- Sustainability: Our metal panels are made from recycled materials. They’re also 100% recyclable at the end of your building’s life. Choose from a variety of cool roofing colors that are designed to reflect the sun’s heat instead of absorbing it into your agricultural building.

- Ease of Installation: Metal panels can be cut to the nearest 1/4 of an inch for easy installation. Most panels offer three feet of coverage which is more time-efficient than pounding out shingles.

- Design Flexibility: There are a variety of options to choose from when it comes to metal panels. We offer a broad selection of styles, profiles, colors and finishes.

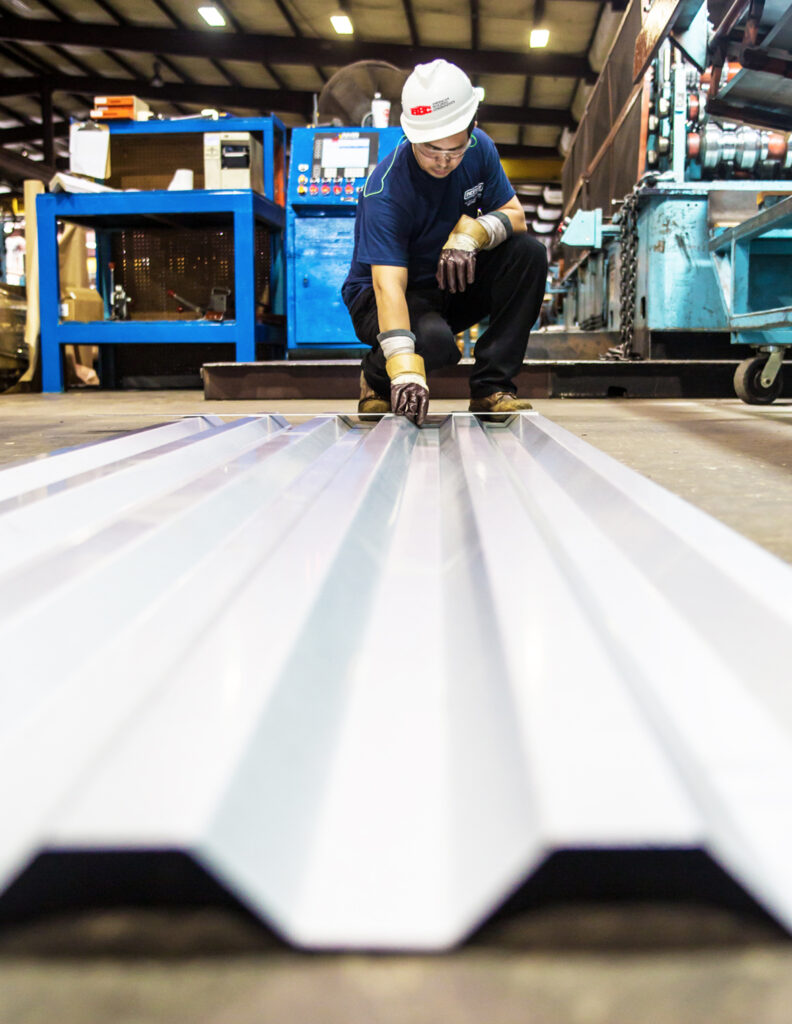

The common panel profile used for this application is Imperial Rib® . It’s designed for durability with two minor ribs which give it strength. It’s also formed with a round top which pushes away moisture.

Metal Panels for Livestock Shelters

Animal confinement imposes specific challenges on panels that aren’t required considerations for residential or commercial uses.

When considering metal panels for a barn or other animal enclosure, here is what you should keep in mind.

What makes animal housing such a challenge?

Animal waste has high ammonia content that can start to corrode metal in as little as five years. With roofs, this corrosion is fueled by airborne fumes; on walls, the culprit is manure or dirt lying against the panels for extended periods. You can minimize both problems with good ventilation and regular maintenance, including keeping the panels clean and immediately repairing any damage.

Important Considerations

- Panel Coatings: More people are opting for Galvalume panels for their livestock housing projects than ever before. And while Galvanized panels perform better than Galvalume in high-ammonia environments such as hog confinement, Galvanized panels are susceptible to white rust (chalking) if exposed to water prior to installation, which is not an issue with Galvalume panels.

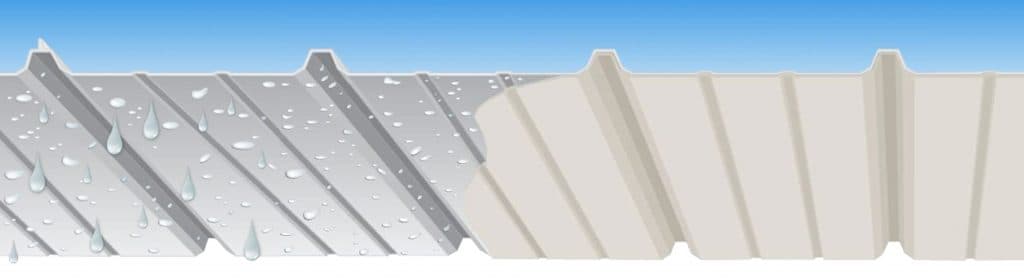

For this reason, many are pairing Galvalume panels with a protective, self-adhesive moisture barrier like ABC’s Drip Stop product, which is applied to the panel’s interior before it is roll-formed. This membrane absorbs moisture when relative humidity (RH) is high, and then releases it back into the atmosphere when the RH falls, thereby preventing the damaging moisture from directly touching the panels. For hog or cattle barns, where dirt and manure tend to pile up against walls, another protective option is to install a polycarbonate panel on the inside of the metal wall panel to reduce contact, making the metal panels easier to keep clean.

No matter which panel you choose, be sure you understand how the coating is measured to that you optimize the durability and long-term corrosion resistance. The best options are the G90 Galvanized or AZ55 Galvalume panels, which have been compared in this article.

- Panel Thickness: The 29-gauge panel is most commonly used for animal confinement, but as mentioned in this article on metal panel gauges, nominal 29-gauge panels come in a range of actual thicknesses. For best results, look for one that’s at least .015 inches thick.

- Design: The design of animal confinement structures is important and can have major impacts on the viability of the building. Dropped ceilings with sophisticated ventilation systems are said to increase efficiency and satisfy environmental run-off inspections, therefore maximizing return on investment. These structures can also be designed to help eliminate ammonia fumes and corrosion- common occurrences in buildings with poor air flow.

- Warranty: As with any purchase, it’s important to check the warranty exclusions when selecting any kind of panel for your projects. For instance, the warranty on a Galvalume panel may not apply when it’s subjected to animal waste or other corrosives. Again, good ventilation and regular maintenance will minimize the chance of problems.

For more information on ABC’s agricultural products, visit our website or contact your local representative today.

What causes condensation on metal panels?

What causes condensation on metal panels?