If you’ve ever gone outside before sunrise, you’ve likely noticed dew on the grass or on your car windows. This is condensation. While we may have learned the basics of this naturally occurring phenomenon in science class, we may need a quick refresher.

Condensation occurs when there’s more water vapor (the invisible, gaseous phase of water) than the air can hold. When the water vapor is cooled off or compressed to its saturation limit—at which point the vapor’s molecular density reaches its maximum threshold—it turns into liquid. Warm air can hold more moisture, but as it cools it reaches its saturation limit and water droplets form. While not a problem on the grass or your car (once you wipe the water away), condensation on metal panels CAN be a problem for your customers. The good news is there’s a simple solution.

What causes condensation on metal panels?

What causes condensation on metal panels?

When temperature and humidity conditions reach dew point, moisture can condense on the underside of metal roofing and potentially cause water damage to the inside of your customer’s building. Those drips from ceilings and surface moisture occur when warm air comes in contact with the cooler roofline or walls.

High interior humidity—a common cause of condensation in metal buildings—can result from heating and air conditioning systems, how the building is used, gas-fired heating components, improper construction techniques or even human respiration, as these all give off moisture vapor.

Effects of condensation on different types of panels:

If there is an abundance of condensation, water droplets will form and can cause damage. In metal buildings, there are a few possible consequences of trapped moisture in wall and roof systems:

- Corrosion of metal components, even on surface-treated metal: When exposed to moisture, metal components can oxidize and weaken, decreasing the life of your customer’s building.

- Degradation/ reduced effectiveness of the thermal performance of insulation

- Mold or mildew growth, which can cause unpleasant odors and increase health risks, particularly for those with allergies or asthma

- Insect infestations

Note: The probability of significant problems will depend on the location and usage of your customer’s building.

Controlling Condensation: What is the Solution?.

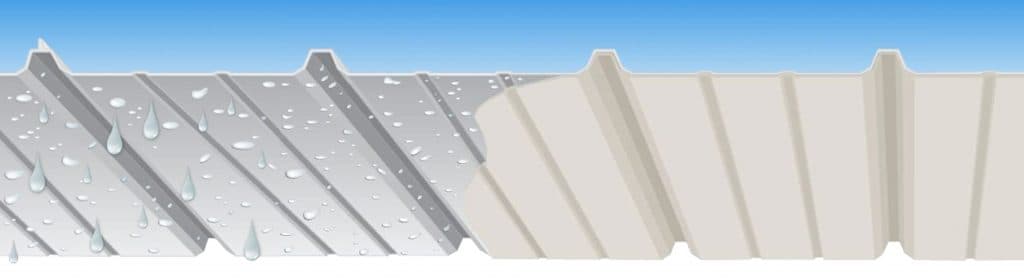

Traditionally, condensation is managed by insulating the metal roof so that the panel temperature never reaches the dew point. This is often accomplished using vinyl-backed fiberglass insulation to prevent humid air from coming into contact with the cooler metal roof (which may be at or below the dew point). If your customers are heating or cooling their building, adding insulation is certainly worth consideration. If they aren’t, there is another option to consider besides the installation of vinyl-backed insulation.

Your customers can consider installing Drip Stop, a patented condensation control membrane, to prevent damage from moisture. Drip Stop (manufactured by ABC) is a felt-like material with a rubber backer that can be applied to the back side of metal panels. The material literally traps and holds the moisture resulting from condensation. When conditions change, the ambient air temperature usually rises, thereby raising the dew point. The moisture is then released from the Drip Stop material back into the air in the form of normal humidity. Drip Stop can be applied to the back of metal coils (either Galvalume® Plus or painted) and then the metal can be roll-formed onto panels.

What are the benefits of this alternative condensation control method?

Drip Stop offers several advantages for your customers:

- Durability: Drip Stop is a very tough, light gray anti-condensation felt that is not susceptible to ripping, tearing or deterioration unlike standard insulation and vapor barriers.

- Low Maintenance: Drip Stop resists dirt and grime, is antimicrobial and is very easy to clean with a hose or pressure washer.

- Corrosion Protection: The rubber backer on the material helps protect the back side of the panel from corrosion (although there is no protection at the panel’s cut edges).

- Easy to Handle: There is no need to roll a vapor barrier over purlins and then seal with tape, which can reduce labor hours and cost. Additionally, the use of Drip Stop is not hindered by windy conditions.

- Safety and Insurance: The material is approved for smoke generation and flame spread per UL® 723 for insurance specifications.

- Acoustic Benefits: Drip Stop helps dampen sound from either inside or outside the building.

- Versatility: Drip Stop is approved for use in residences, warehouses, industrial plants, sports arenas, schools, storage buildings, garages, animal confinement facilities and more.

- Cost-Savings: Drip Stop is up to 25 percent less expensive as compared to traditional solutions.

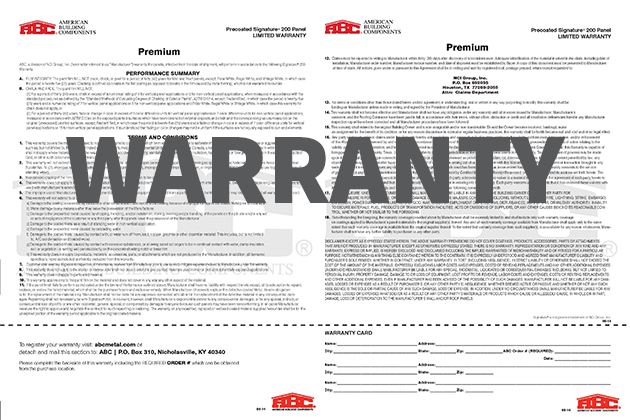

- Warranty-Backed: Drip Stop features a 20-year adhesion warranty to ensure longevity.

The Bottom Line:

There’s no need for the damaging effects of condensation to put a damper on your customer’s metal building project. With a simple solution like Drip Stop, you customers can protect their assets and prevent costly and time-consuming repairs.

For more information on Drip Stop and how it can be applied to ABC’s PBR, Imperial Rib® and Retro-R® panels, visit our website or contact your local sales representative.

What causes condensation on metal panels?

What causes condensation on metal panels?